86211 Ultrasonic Thickness Gauge

Non-destructive testing for metal, glass, ceramics, and plastics

Includes four types of probes to measure a wide variety of materials

Two measurement modes: QC Mode / Statistics Mode

Wide measuring range: 0.8 mm–600 mm with a highly sensitive dual-crystal probe

Switchable automatic gain

The 86211 ultrasonic thickness gauge uses the ultrasonic pulse reflection principle to measure thickness. It is compatible with four probe types: standard probe, micro-diameter probe, coarse crystal probe, and high-temperature probe. This device is designed for measuring the thickness of metals (such as steel, aluminum, and copper), plastics, ceramics, glass, and other materials capable of transmitting ultrasonic waves. Featuring a professional-grade timing chip, it delivers a resolution of up to 0.001 mm.

In many industries, monitoring wall thickness is crucial for assessing material condition and ensuring structural safety. The 86211 ultrasonic thickness gauge is widely used for inspecting the thickness of components and metallic structures, determining whether repairs or replacements are needed. It is ideal for applications in industries such as petroleum, chemical processing, metallurgy, shipbuilding, aviation, and aerospace.

Parameters

1. Probe specifications and parameters

| Probe | Standard Probe | Micro-diameter Probe | Coarse Crystal Probe | High Temperature Probe |

|---|---|---|---|---|

| Probe Model | 5MHZφ10 | 7MHZ PT-06 | 2MHZ ZT-12 | 5MHZ GT-12 |

| Minimum Measuring Area | φ10mm | φ6mm | φ12mm | φ12mm |

| Probe Size | φ18*26mm | φ15*25mm | φ18*28mm | φ43*48mm |

| Measuring Range(45#steel) | 0.8-600mm | 0.75-80mm | 3-200mm | 3-200mm |

| Accuracy(H is the standard value) | H<10mm:±0.05mmH≥10mm:±0.5%H | H<10mm:±0.05mmH≥10mm:±0.5%H | H<10mm:±0.1mmH≥10mm:±0.5%H | H<10mm:±0.05mmH≥10mm:±0.5%H |

| Pipe Measurement Lower Limit(45# steel) | φ20*3mm | φ20*2mm | φ30*4mm | φ30*4mm |

| Exposure Temperature | -10~60℃ | -10~60℃ | -10~60℃ | -10~500℃ |

| Application | Measure conventional workpieces | Measure surfaces and small workpieces | Cast iron and some materials with large crystal particles | Measure high temperature workpieces |

2. Host parameters

| Parameter | Value |

|---|---|

| Resolution | 0.8-10mm:0.001mm10-100mm:0.01mm100-600mm:0.1mm |

| Sound Velocity Range | 1000~19999m/s |

| Display | 240 * 160 dot matrix LCD |

| Unit | mm/inch |

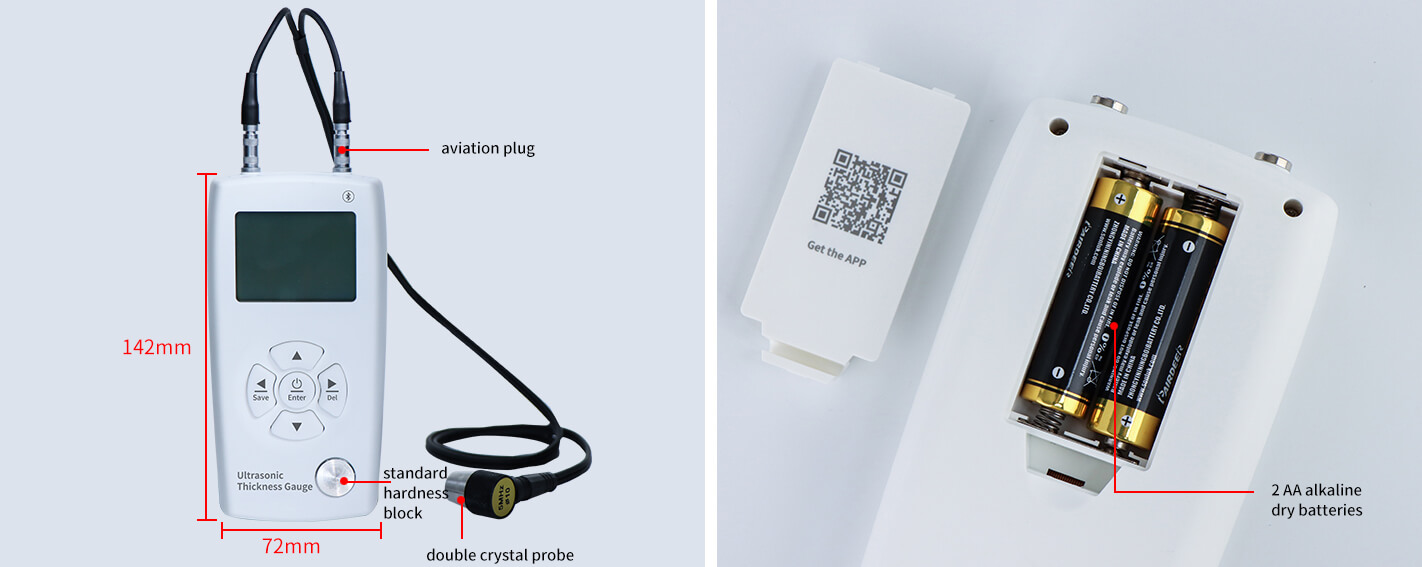

| Power Supply | 2pcs of 1.5V AA alkaline battery |

| Host Size | 142 * 72 * 28 mm |

| Weight | About 230g |

| Operation Temperature Range | -10~50℃,0~85%RH(No condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(No condensation) |

Features

High-performance timing chip for fast and accurate readings

The 86211 calculates material thickness by measuring the time between the emitted pulse and its echo, combined with the material’s sound velocity. Its precision timing chip ensures highly accurate measurements.

Dual-crystal ultrasonic probe

The probe features a dual-crystal transducer with two independent crystals separated by an acoustic barrier—one sends ultrasonic pulses, the other receives them. This design enhances sensitivity and reduces interference. The probe housing is made of durable stainless steel.

Compatible with four types of probes and automatic probe recognition

The device supports four probe types: standard, micro-diameter, coarse crystal, and high-temperature. It automatically recognizes the probe type and adjusts the display interface accordingly.

Switchable automatic gain

Since materials vary in how they conduct sound, the device allows users to freely switch gain levels. This amplifies ultrasonic signals in less conductive materials, ensuring accurate data capture.

High precision meets national metrology standards

The 86211 offers ±0.05 mm accuracy for materials 0.8–10 mm thick, and ±0.5% of reading for 10–600 mm thickness. It meets the standards of China’s national metrology institute.

E-E (Echo-Echo) measurement mode

When measuring coated or painted surfaces, the E-E mode allows users to accurately measure the substrate thickness beneath coatings, without needing to remove them.

Bluetooth connectivity and mobile app integration

The built-in Bluetooth module lets users connect to a smartphone app for storing and sharing measurement data easily.

PC Software Function

The device supports PC software connection, enabling quick thickness measurements and direct Excel data export. It ensures convenient data storage and sharing.

Large data storage capacity (999 records)

The gauge can store up to 999 measurement records, which can be reviewed anytime to prevent data loss.

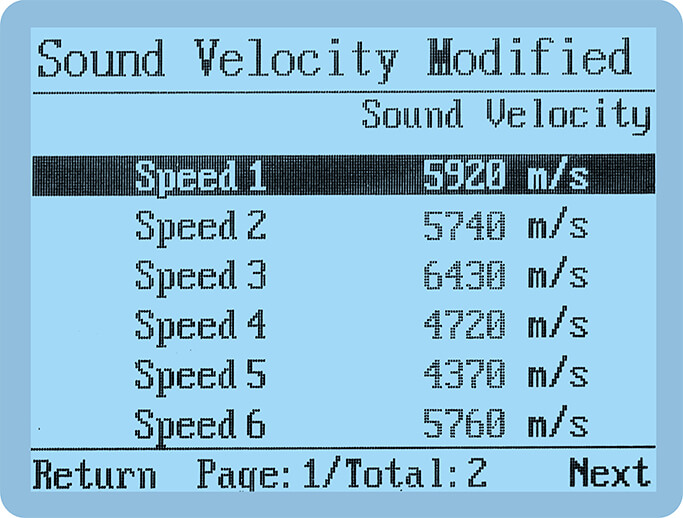

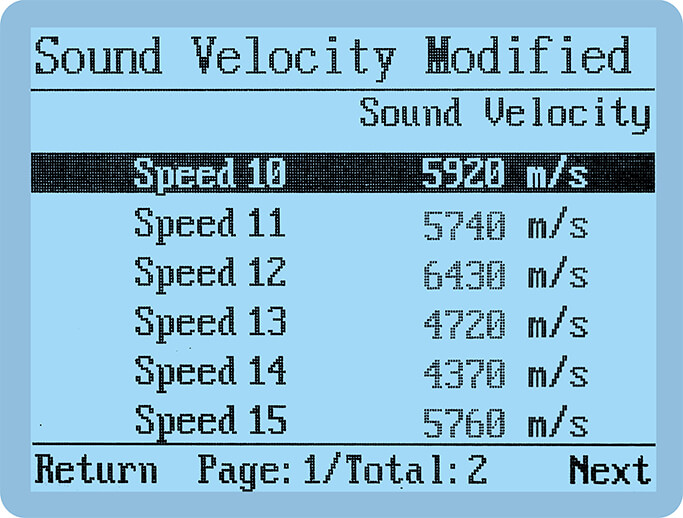

Customizable sound velocity storage for 18 materials

Users can store custom sound velocity values when measuring materials not preloaded in the device. There are 9 slots each for "Set by thickness" and "Manual input" modes, which can be modified and saved as needed.

Set by thickness interface

Manual input interface

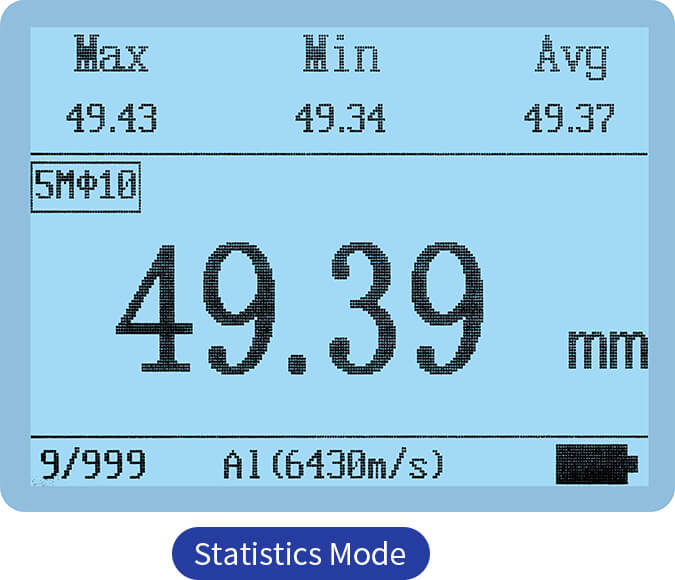

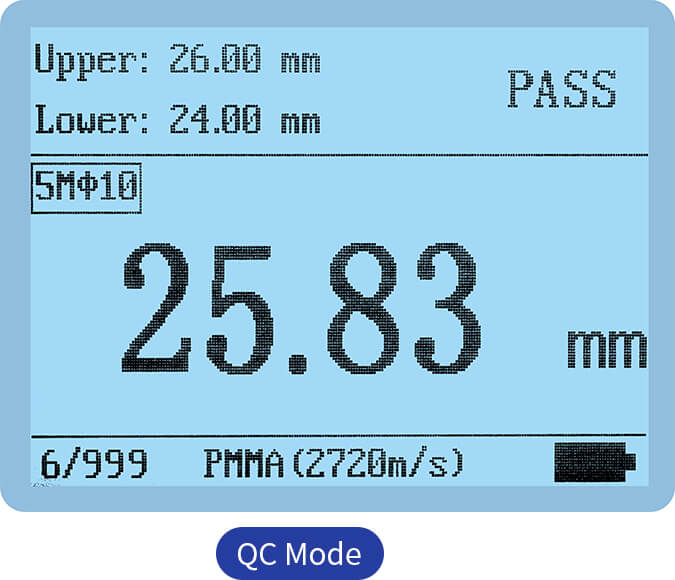

Two measurement modes: QC Mode / Statistics Mode

In QC Mode, users can set upper and lower thresholds, with NG prompts identifying problem areas. Statistics Mode automatically calculates and displays maximum, minimum, and average readings.

Statistics mode

QC mode

Built-in sound velocity of multiple materials

The 86211 includes built-in velocities for various metals (iron, copper, aluminum), plastics, ceramics, plexiglass, and other materials, so users don’t have to look them up separately.

Wide measurement range

With the standard probe, users can measure material thicknesses ranging from 0.8 mm to 600 mm, covering most testing needs.

Accurate measurement across a variety of materials

As a non-destructive testing device, the 86211 uses a dual-crystal transducer and a small amount of couplant to measure the thickness of steel, plastics, glass, ceramics, and more. For curved surfaces, the probe should be applied perpendicular to the surface axis for accurate results.

Comfortable grip with non-slip silicone keys

The device features a durable ABS housing with non-slip silicone keys, ensuring a comfortable grip and ease of use.

Easy-to-read LCD screen with backlight support

Clearly labeled keypad and intuitive menu navigation

Switchable between inch and mm

Multiple language options available

Software Download

The 86211 Ultrasonic Thickness Gauge is equipped with an APP that supports Android OS version 7.0 and higher. It can be installed through the following ways:

1) Scan the QR code on the instrument with your mobile browser, follow the instructions to download and install.

2) Search for "UT and HL" (not case sensitive) in the Google Play to install the application.