86225+F500 Plating Thickness Gauge

Ideal for Measuring Ultra-Thin Coatings Below 10μm

Utilizes advanced digital oscillation technology

Supports continuous measurement

Offers 1 to 5-point calibration options

The 86225+F500 is a high-precision plating thickness gauge featuring a separate host and probe design. It includes the 86225+F500 multi-probe coating thickness gauge host and the F500 probe.This instrument is specifically designed for measuring non-magnetic coatings—such as copper, zinc, tin, and chromium—on ferromagnetic metal substrates like iron. The 86225+F500 delivers exceptional measurement accuracy and repeatability, making it ideal for detecting ultra-thin coatings under 10μm.Widely used in metal processing, hardware manufacturing, and similar industries, it’s especially well-suited for testing small components thanks to its minimum measurement area diameter of just 7 mm.

Application

86225+F500 plating thickness gauge is widely used in metal processing industry, hardware and other industries.

86225+F500 Plating Thickness Gauge tests small size material

86225+F500 Plating Thickness Gauge tests ultra-thin coatings

86225+F500 Plating Thickness Gauge tests special-shaped material

86225+F500 Plating Thickness Gauge tests with fixture

Parameters

86225 plating thickness gauge host parameters

| Parameter | Value |

|---|---|

| Display | 240×160 dot matrix LCD |

| Power Supply | 4pcs of 1.5V AAA alkaline battery |

| Operation Temperaturerange | 0℃-50℃ |

| Storage Temperaturerange | -20℃-60℃ |

| Host Size | 148*76*26 mm (L*W*H) |

| Weight (include battery) | 194g |

F500 probe parameters

| Parameter | Value |

|---|---|

| Measuring Principle | Magnetic Induction |

| Measuring Range | 0.0-500μm |

| Resolution | 0.1μm: 0μm - 99.9μm 1μm: 100μm - 500μm |

| Repeatability | ≤ ± (0.8% of reading + 0.1μm)Test with fixture |

| Accuracy | ≤±(2%reading+0.3μm) after calibration of 1-5 points |

| Unit | μm / mil |

| Measuring Interval | 1.5s |

| Minimum Measuring Area | Ø = 7mm |

| Minimum Curvature | Convex:1.5mm / Concave:10mm |

| Minimum Substrate Thickness | 0.1mm |

| Calibration | Support zero reference adjustment and 1 to 5-points calibration |

| Probe Size | 110*15 mm (Without connecting cable) |

| Probe Weight (include battery) | 81g |

Features

Accurate Measurement of Small Components

Equipped with the F500 ultra-small probe, this gauge excels in measuring coatings on tiny parts like screws and bolts.

Cutting-Edge Technology for Superior Accuracy

The F500 probe employs digital oscillation and high-speed ADC acquisition to maintain excellent stability and accuracy—even for ultra-thin coatings.

Complies with Global Standards

The device meets both national and international metrology standards and has been certified by leading Chinese measurement authorities.

Flexible Calibration Options

Supports zero-point and multi-point calibration (up to 5 points). Includes 7 standard calibration foils of various thicknesses. Users can fine-tune the calibration curve based on these foils or actual samples to improve accuracy.

Robust Data Statistics Functionality

Capable of storing up to 9 measurement readings, the gauge automatically calculates maximum, minimum, average, and standard deviation values.

Durable Hard Probe

The rugged probe construction ensures long-lasting and reliable performance.

Optional Fixture for Enhanced Stability

A dedicated fixture (sold separately) is available to enhance measurement stability and reduce human error during operation.

Multi-language display options

Unit selection: μm / mil

Adjustable auto-off timer (1–9 minutes)

Qualifications and Standards

86225+F500 plating thickness gauge conforms to the following standards:

GB/T 4956-2003 Non-magnetic Coatings on Magnetic Substrates-Measurement of Coating Thickness-Magnetic Method

DIN EN ISO 2808 Paints and Varnishes-Determination of Film Thickness

JJG-818-2005 Verification Regulation of Magnetic and Eddy Current Measuring Instrument for Coating Thickness

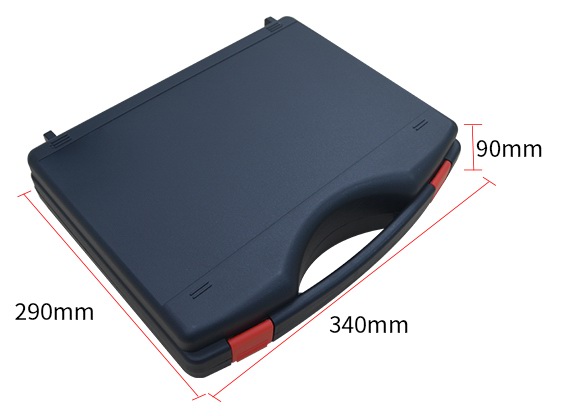

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | 86225+F500 Plating Thickness Gauge | 1 | pcs |

| 2 | F500 pProbe | 1 | pcs |

| 3 | Fe Zero-adjustment Plate | 1 | pcs |

| 4 | Standard Films | 7 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Certificate / Warranty Card | 1 | pcs |

| 7 | Plastic Engineering Case | 1 | pcs |

FAQ

-

1. The difference between 86225 and other coating thickness gauges

Compared with several other coating thickness gauges, 86225 has higher measurement accuracy and data repeatability. With a special test fixture, it can be used to accurately measure ultra-thin coatings below 10μm, small size and special-shaped workpieces. It supports zero adjustment and multi-point calibration. The measurement results can be more accurate after calibration through standard films or uncoated workpieces.