86225+N1500 Ultra-thin Coating thickness Tester

Accurately Measures Coatings Under 10μm

Eddy current measuring principle

Measure the anodic oxide layer thickness on aluminum

Measuring range: 0-1500μm

The 86225+N1500 is a split-type coating thickness tester composed of a main unit and the digital N1500 probe. Utilizing advanced eddy current induction technology, it delivers high measurement accuracy and repeatability, making it ideal for ultra-thin coatings, small components, and uniquely shaped materials.

Application

The 86225+N1500 is well-suited for use in production inspections, construction acceptance, and on-site measurements at trade shows or sales venues. It enables fast, non-destructive thickness measurement of non-conductive coatings on non-magnetic metal substrates. Commonly used across various industries such as aerospace, construction materials, mechanical manufacturing, chemical engineering, and instrumentation.

86225+N1500 Plating Thickness Gauge tests with fixture

86225+N1500 Plating Thickness Gauge tests aluminum window sill

86225+N1500 Plating Thickness Gauge tests ultra-thin coatings

86225+N1500 Plating Thickness Gauge tests cell phone case

Parameters

86225 Plating thickness tester host parameters

| Parameter | Value |

|---|---|

| Display | 240×160 dot matrix LCD |

| Power Supply | 4pcs of 1.5V AAA alkaline battery |

| Operation Temperaturerange | 0℃-50℃ |

| Storage Temperaturerange | -20℃-60℃ |

| Host Size | 148*76*26 mm (L*W*H) |

| Weight (include battery) | 194g |

N1500 probe parameters

| Parameter | Value |

|---|---|

| Measuring principle | Eddy current |

| Substrate | Non-ferromagnetic metal |

| Measuring Range | 0.0-1500μm |

| Resolution | 0.1μm: 0μm - 99.9μm 1μm: 100μm - 999μm 0.01mm: 1.00mm – 1.50mm |

| Repeatability | ≤ ± (0.8% of reading + 0.1μm) Test with fixture |

| Accuracy | ≤±(2%reading+0.3μm) after 5 points calibration |

| Unit | μm / mil |

| Measuring Interval | 0.8s |

| Minimum Mmeasuring Area | Ø = 7mm |

| Minimum Curvature | Convex:1.5mm / Concave:10mm |

| Minimum Substrate Thickness | 0.05mm |

| Calibration | Support zero reference adjustment and 1 to 5-points calibration |

| Probe Size | 110*15 mm (Without connecting cable) |

| Probe Weight | 81g |

Features

Digital Probe for Stable Readings

The N1500 digital probe processes measurement signals directly at the probe, significantly reducing the risk of interference from the external environment and ensuring consistent, repeatable results.

Measure Ultra-Thin Anodized Coatings with Precision

Thanks to digital oscillation technology and high-speed ADC data acquisition, the tester accurately measures ultra-thin coatings under 10μm, providing stable and reliable data.

Optional Fixtures and Clamps for Improved Stability

Dedicated fixtures are available to eliminate human error, enabling consistent measurements with a repeatability of up to 0.1μm.

Supports Zero-Adjustment and Multi-Point Calibration

For improved measurement accuracy, the device offers zero-adjustment and supports multi-point calibration. It comes equipped with a special zero adjustment plate and standard calibration films.

Advanced Data Statistics Functionality

The tester includes built-in data statistics, automatically calculating the maximum, minimum, average, and standard deviation across the latest nine measurements.

Durable, High-Hardness Probe

Engineered with a hardened probe and enhanced durability, the device is built for long-term use in industrial environments.

Wide measuring range

Unit switching capability

Multiple display language options

Auto shut-off time adjustable from 1 to 9 minutes

Qualifications and Standards

86225+N1500 plating thickness gauge conforms to the following standards:

GB/T 4957-2003 Non-conductive coatings on non-magnetic basis metals-Measurement of coating thickness-Eddy current

DIN EN ISO 2808 Paints and Varnishes-Determination of Film Thickness

JJG-818-2005 Verification Regulation of Magnetic and Eddy Current Measuring Instrument for Coating Thickness

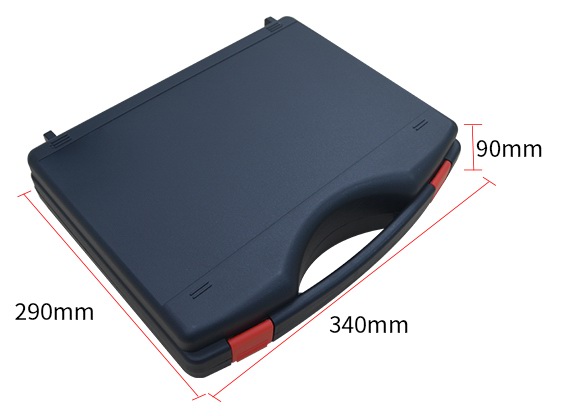

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | 86225+N1500 PlatingThickness Tester | 1 | pcs |

| 2 | N1500 Probe | 1 | pcs |

| 3 | NFe Zero-adjustment Plate | 1 | pcs |

| 4 | Standard Films | 7 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Certificate / Warranty Card | 1 | pcs |

| 7 | Plastic Engineering Case | 1 | pcs |

FAQ

-

1. The difference between 86225 and other coating thickness gauges

Compared with several other coating thickness gauges, 86225 has higher measurement accuracy and data repeatability. With a special test fixture, it can be used to accurately measure ultra-thin coatings below 10μm, small size and special-shaped workpieces. It supports zero adjustment and multi-point calibration. The measurement results can be more accurate after calibration through standard films or uncoated workpieces.