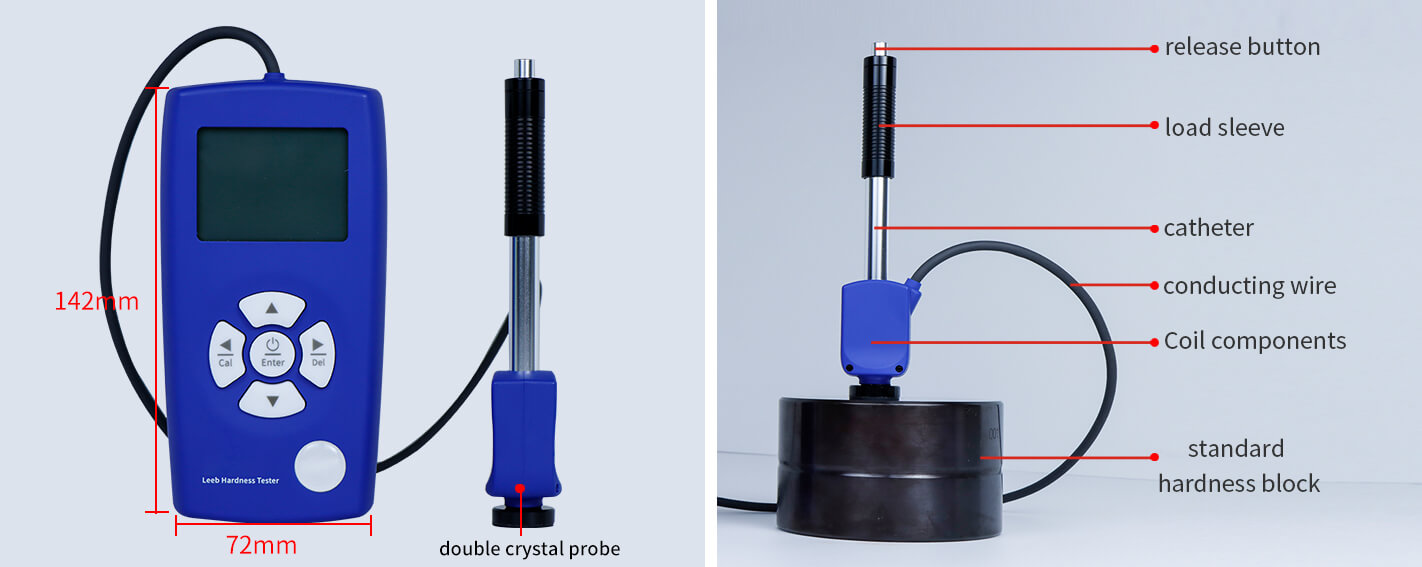

86251D Leeb Hardness Tester

Ideal for testing iron, copper, steel, and other metal materials

Utilizing advanced digital probe technology for precise testing

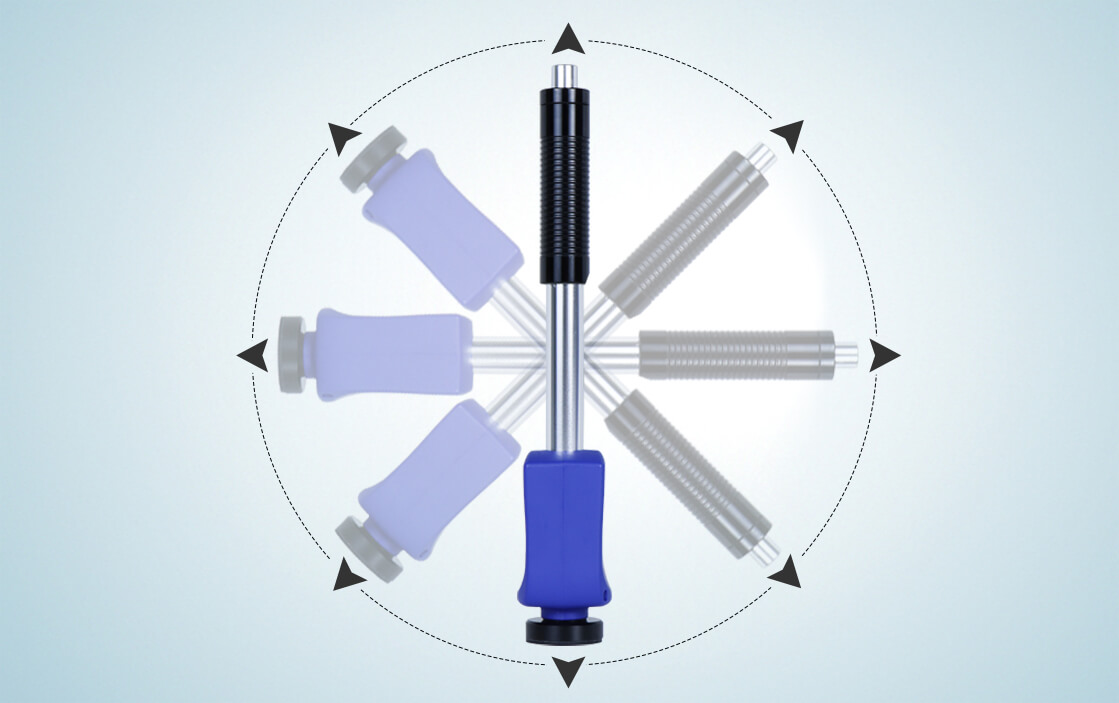

Equipped with a built-in direction sensor for automatic compensation of measurement deviations across different impact angles

Offers multiple selectable hardness scales—no need for tedious manual reference charts

Hardness refers to a material’s ability to resist localized deformation—typically measured by the resistance to indentation by a hard object. The 86251D Leeb Hardness Tester evaluates hardness based on the Leeb rebound principle and is capable of testing various metal materials. It features cutting-edge digital probe technology, with digital signal processing executed directly within the probe, minimizing interference and ensuring high accuracy.

The integrated orientation sensor automatically corrects for impact direction, improving data precision. The device supports multiple hardness scales—Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), Rockwell (HRA/HRB/HRC)—which are easily convertible to eliminate manual calculations. In addition to hardness, the tester can also measure material strength. With its highly portable design, the 86251D offers an outstanding user experience, especially for on-site or field testing.

Applicable Materials

The 86251D Leeb Hardness Tester is suitable for materials such as steel, cast steel, alloy steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloys, copper-zinc alloys, copper-tin alloys, pure copper, and forged steel. It’s widely applicable in areas including machine tool guides, automotive chassis, heavy machinery parts, mold cavities, bearings, pressure vessels, and assembled equipment—making it an invaluable tool for manufacturers in product quality inspection and process optimization.

Parameters

| Probe | Impact device D |

|---|---|

| Hardness Scales | HL, HV, HB, HS, HRA, HRB, HRC |

| Measurement Range | HLD(170-960)/HV(83-976)/HB(30-651)/HRC(17.6-68.5)HS(26.4-99.5)/HRB(13.5-100)/HRA(60-85.8) |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL typical |

| Repeatability | 6HL (factory standard) |

| Display | 240 * 16 dot matrix LCD |

| Power Supply | 2 AA alkaline dry batteries |

| Host Size | 142*72*28 mm |

| Probe Size | 148*31*25 mm |

| Weight | 247g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Advanced Digital Probe Technology

The device leverages advanced digital probes, processing signals directly within the probe. This setup reduces interference and delivers excellent testing accuracy.

Multi-Angle Measurement with Automatic Compensation

Thanks to a built-in direction sensor, the probe can automatically adjust for measurement discrepancies caused by different impact angles—enabling accurate readings regardless of the testing position.

Multiple Hardness Scale Conversion

The tester supports and switches seamlessly between Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS), and Rockwell (HRA/HRB/HRC) scales. This eliminates the need for manual reference tables. It can also measure material strength, extending its functionality.

High Precision, Certified Accuracy

With an accuracy of ±6HL, the 86251D meets the standards of China’s national metrology institute, ensuring reliable and certified results.

Quality Control Support

Users can set upper and lower limit thresholds to automatically determine whether materials meet predefined hardness standards—ideal for batch inspections.

Statistical Functionality

The tester automatically calculates and displays the maximum, minimum, and average values of the latest 9 measurements.

User Calibration Support

Users can calibrate the device using standard parts to eliminate any potential measurement errors.

Bright LCD Display for Low-Light Use

The device features a high-brightness LCD screen, making it easy to read in dark environments.

Long Battery Life

Powered by two AA alkaline batteries, the tester can operate continuously for over 100 hours.

Includes Standard Leeb Hardness Test Block

A standard test block is included, reducing ongoing testing costs by eliminating the need for frequent replacements.

Qualifications and Standards

86251D Leeb Hardness Tester conforms to the following standards:

GB/T 17394.1 Metallic materials-Leeb hardness test-Part 1: Test method

GB/T 17394.2 Metallic materials-Leeb hardness test-Part 2: Verification and calibration of hardness tester

GB/T 17394.4 Metallic materials-Leeb hardness test-Part 4: Tables of hardness values conversion

JB/T 9378-2001 Industry standard of Leeb hardness tester

JJG 747-1999 Verification regulation of Leeb hardness tester

Packing

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Leeb Hardness Tester | 1 | Set |

| 2 | Standard Leeb Hardness Block | 1 | pcs |

| 3 | Nylon Brush | 1 | pcs |

| 4 | Small Support Ring | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Calibration Report | 1 | pcs |

| 7 | Certificate / Warranty Card | 1 | pcs |

| 8 | Plastic Case | 1 | pcs |

FAQ

-

What is the thinnest thickness a durometer can measure and what is the thinnest thickness after coupling?

Leeb hardness tester is only suitable for large and heavy workpieces, small and thin parts must be coupled to a solid support for testing; D-type impact device is measured by the minimum mass of 5kg, the minimum thickness of 25mm, if the weight or thickness does not meet the requirements, must be coupled to a solid support for testing, coupled to the minimum thickness of the measured object is 3mm.